In today's world, sustainability is becoming increasingly important. As consumers become more aware of the impact that their purchases have on the environment, businesses are looking for ways to reduce their carbon footprint. One way that businesses can do this is by using RPET plastic packaging boxes. RPET, or recycled polyethylene terephthalate, is a type of plastic that is made from recycled materials. In this article, we will explore the benefits of using RPET plastic packaging boxes and why they are the sustainable solution for your packaging needs.

What are RPET Plastic Packaging Boxes?

RPET plastic packaging boxes are made from recycled materials, specifically recycled polyethylene terephthalate. This type of plastic is commonly used in water bottles, food containers, and other types of packaging. RPET plastic packaging boxes are a sustainable alternative to traditional plastic packaging because they are made from recycled materials and can be recycled again after use.

Benefits of Using RPET Plastic Packaging Boxes

1. Environmental Benefits

The most significant benefit of using RPET plastic packaging boxes is their environmental impact. By using recycled materials, businesses can reduce their carbon footprint and contribute to a more sustainable future. RPET plastic packaging boxes are also recyclable, which means that they can be reused again and again, reducing the amount of waste that ends up in landfills.

2. Cost-Effective

RPET plastic packaging boxes are cost-effective because they are made from recycled materials. This means that businesses can save money on raw materials and production costs. Additionally, because RPET plastic packaging boxes are recyclable, businesses can save money on waste disposal costs.

3. Durable

RPET plastic packaging boxes are durable and can withstand the rigors of shipping and handling. This means that businesses can use them to protect their products during transportation, reducing the risk of damage and returns.

4. Versatile

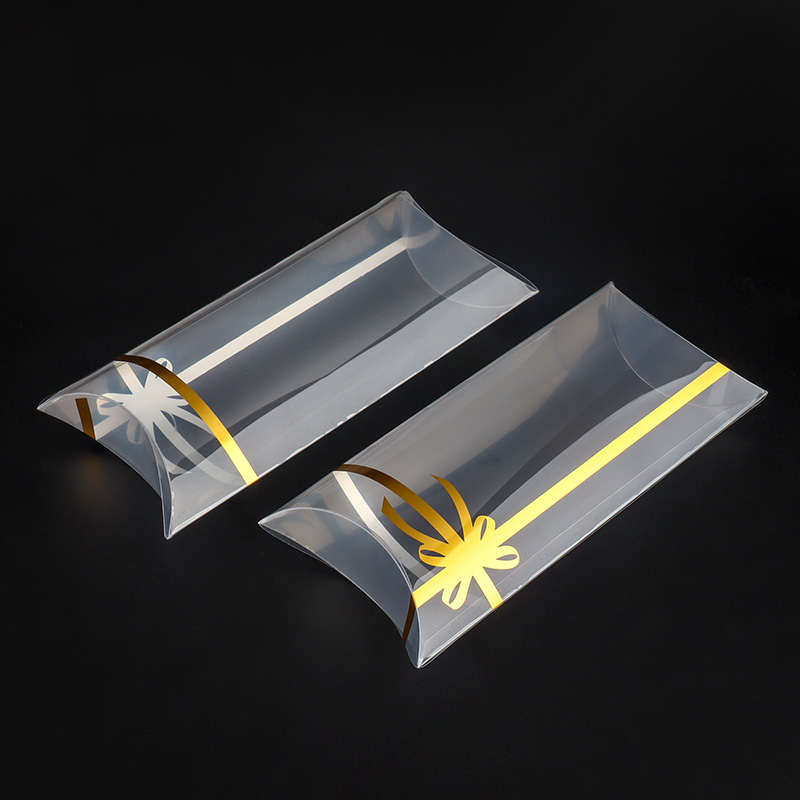

RPET plastic packaging boxes are versatile and can be used for a wide range of products, including food, cosmetics, electronics, and more. They are available in a variety of shapes and sizes, making them suitable for any product.

5. Branding Opportunities

RPET plastic packaging boxes can be customized with branding and logos, providing businesses with an opportunity to promote their brand and increase brand recognition.

How RPET Plastic Packaging Boxes are Made

RPET plastic packaging boxes are made from recycled materials, specifically recycled polyethylene terephthalate. The process of making RPET plastic packaging boxes involves the following steps:

1. Collection and Sorting

The first step in making RPET plastic packaging boxes is to collect and sort the recycled materials. This involves collecting plastic bottles and other types of plastic packaging and sorting them by color and type.

2. Cleaning and Shredding

Once the plastic has been sorted, it is cleaned and shredded into small pieces. This process removes any labels, caps, or other contaminants from the plastic.

3. Melting and Extruding

The shredded plastic is then melted and extruded into thin sheets. These sheets are then cut into the desired shape and size for the packaging boxes.

4. Printing and Assembly

The RPET plastic packaging boxes can be printed with branding and logos before being assembled. The boxes are then ready to be used for packaging products.

Conclusione

RPET plastic packaging boxes are a sustainable alternative to traditional plastic packaging. They are made from recycled materials, can be recycled again after use, and offer a range of benefits, including cost-effectiveness, durability, versatility, and branding opportunities. By using RPET plastic packaging boxes, businesses can reduce their carbon footprint and contribute to a more sustainable future.

Prodotti correlati