Le scatole di plastica sono attualmente tra gli oggetti più utilizzati nella vita quotidiana. PVC/PET/PP/PS e altri materiali sono utilizzati per produrre scatole di plastica, che comprendono scatole pieghevoli trasparenti, cilindri, scatole di copertura per il cielo e per la terra, sacchetti con maniglia, cartoncini da appendere e altri articoli correlati. La stampa offset UV, la serigrafia, la bronzatura/argentatura, la glassatura e altri effetti di stampa possono essere ottenuti sugli articoli in plastica, aumentando l'attrattiva dei prodotti dei clienti e incrementando le vendite dei prodotti. Le scatole di plastica sono comunemente utilizzate per imballare e conservare una serie di oggetti. Sul mercato esistono diverse varietà di scatole di plastica, ognuna con le proprie finalità e caratteristiche. In questo articolo verranno analizzate le numerose varietà di scatole di plastica e le loro caratteristiche uniche.

1. PP plastic box

PP is a thermoplastic that is semi-crystalline. It is resistant to many organic solvents and acid-base corrosion and has a good impact resistance and robust mechanical qualities. It is a common polymer substance that is frequently utilized in industry. The pp storage box is basically a regular storage box made of regular PP material, not food-grade PP. PP is a resin with increased strength, density, and clarity. PP has the lowest density, the greatest melting point, and the lowest cost of any large-volume thermoplastic container. It may be formed into non-invasive films or rigid food packing containers.

The plastic used in PP food packaging is extremely robust and chemically resistant, making it a good choice for preserving foodstuffs that must be transported in hostile settings. They have a high melting point and can endure high temperatures, making them ideal for usage in both hot and cold conditions. The fact that the PP boxes are dishwasher and microwave safe adds to their versatility.

2. PET plastic box

PET materials have high transparency, hardness, biaxial tensile strength, toughness, high temperature resistance, corrosion resistance, and aging resistance. PET film materials typically have a smooth transparent surface and a frosted surface, but the sand surface is extremely fine, akin to a polished surface layer, and the polished surface is created on the PET surface, as opposed to PC, which is mechanically obtained. The method is obtained by the mechanical rolling process's sand surface, which decides that its surface is not as evident as the PC sand surface.The melting point of PET is much higher than that of PP, about 260 degrees Celsius, and affected by the processing conditions, it will not shrink when it is below 180 degrees Celsius. Injection blown film-molded PET bottles are the fastest growing plastic packaging in food packaging applications, and PET can also replace PVC materials for packaging of dry cooking oil.

3. PVC plastic box

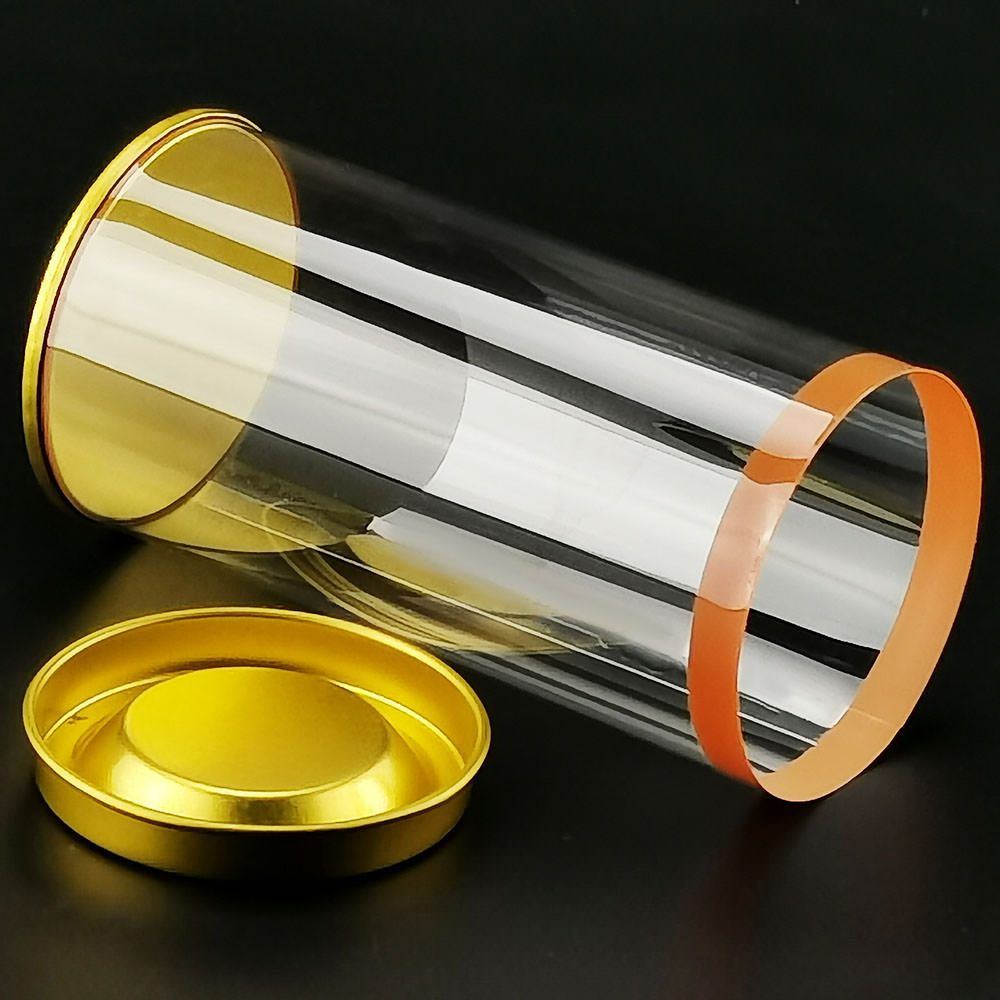

PVC is a high molecular weight polymer that replaces a hydrogen atom in polyethylene with a chlorine atom.PVC's most essential property is flame retardancy, which is why it is commonly employed in fire defense applications. PVC boxes are commonly utilized in the packaging sector due to their great transparency. They are lightweight, flexible, and low-density, making them ideal for storage and transportation. Furthermore, PVC boxes are watertight, corrosion-resistant, and chemically resistant. They have strong electrical qualities as well, making them suitable for application in the electronics sector.

The packing box produced from it has the following features:

1The clear packing box has a suitable construction, providing the goods with a stable protective environment and an exquisite look design.

2In terms of materials, pick ecologically friendly and anti-scratch high-transparency materials that will not only prevent product damage during shipping and storage, but will also fulfill processing, printing, and environmental protection criteria.

3Transparent packing box with a lovely and high-quality look design.

Plastic boxes are increasingly used in electronics, hardware, presents, cosmetics, toys, stationery, and other small-sized items. It is critical to select the correct type of plastic box based on your requirements. Packaging things in clear boxes is a free and inexpensive advertisement that increases the value of the product. PVC, PP, PET folding boxes, transparent color boxes, frosted plastic boxes, hook boxes, heaven and earth cover boxes that can be glued, plugged, and buckled are all examples of plastic boxes.

Prodotti correlati