In the ever-evolving landscape of packaging, tube packaging with tinplate lids has emerged as a versatile and sustainable solution. Let’s delve into the intricacies of this innovative packaging method, exploring its history, manufacturing processes, applications across diverse industries, and its promising future.

I. Introduction

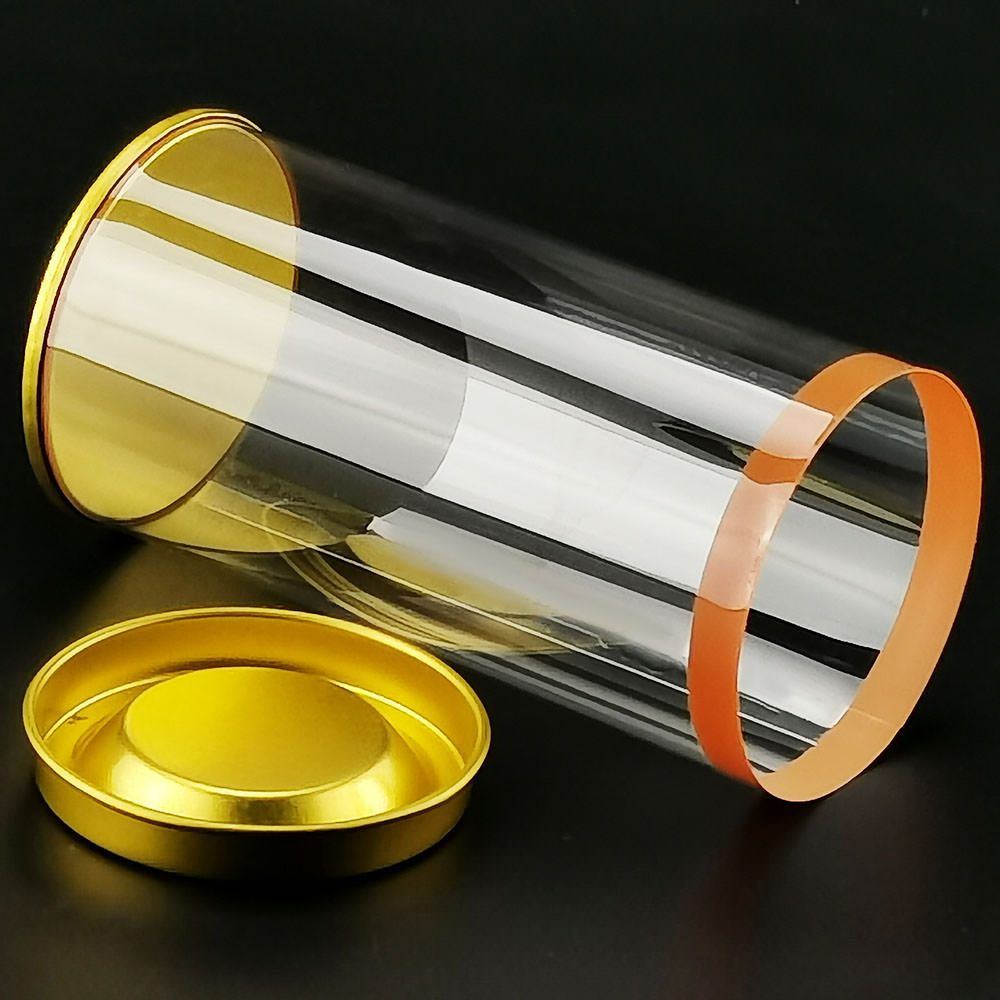

A. Definition of Tube Packaging with Tinplate Lids

Tube packaging with tinplate lids involves encapsulating products within cylindrical tubes sealed with lids made from tinplate, a thin steel sheet coated with a layer of tin. This packaging method combines the robustness of steel with the malleability of tin, ensuring both durability and flexibility.

B. Historical Significance

The origins of tinplate can be traced back to the 17th century when artisans in England discovered the technique of coating iron with tin to prevent rusting. Over centuries, this method evolved, eventually leading to the development of tinplate lids for various packaging applications.

C. Importance in Modern Packaging Industry

In the contemporary packaging landscape, where sustainability, durability, and aesthetics are paramount, tube packaging with tinplate lids stands out as an ideal choice. Its ability to preserve product freshness, coupled with its eco-friendly nature, makes it a preferred option for many industries.

II. The Evolution of Packaging

A. Early Packaging Methods

Before the advent of modern packaging techniques, products were stored and transported in crude containers made from materials like clay, wood, and animal hides. These containers lacked the sophistication and protection that modern packaging offers.

B. Introduction of Tinplate Lids

The introduction of tinplate lids marked a significant milestone in the packaging industry. This innovation allowed products to be securely sealed, protecting them from contaminants, moisture, and air, thereby extending their shelf life.

C. Emergence of Tube Packaging

Tube packaging, characterized by its cylindrical shape, gained prominence during the industrial revolution. The combination of this shape with tinplate lids revolutionized the way products were packaged, making it convenient for consumers while ensuring the integrity of the contents.

III. Understanding Tinplate Lids

A. Composition and Properties

Tinplate lids are crafted from thin steel sheets coated with a layer of tin. This combination imparts strength to the lid, making it resistant to corrosion and ensuring the safety of the packaged contents.

B. Manufacturing Process

The manufacturing process involves several intricate steps, including shearing, pickling, cold rolling, annealing, and coating. Each step is crucial in ensuring the quality and durability of the tinplate lids.

C. Benefits of Tinplate Lids

Tinplate lids offer a myriad of benefits, including high recyclability, resistance to external elements, and ease of printing for branding purposes. Their ability to withstand extreme temperatures and pressures makes them ideal for various applications.

IV. Advantages of Tube Packaging with Tinplate Lids

A. Preservation of Product Freshness

One of the primary advantages of tube packaging with tinplate lids is its ability to preserve the freshness and quality of the enclosed products. The secure seal formed by the tinplate lids prevents exposure to air and moisture, ensuring the product remains uncontaminated.

B. Enhanced Durability and Protection

The robust nature of tinplate lids provides enhanced protection to the packaged items. Whether it’s cosmetics, pharmaceuticals, or food products, tinplate lids act as a sturdy barrier, safeguarding the contents from external factors such as light, heat, and physical damage during transit.

C. Eco-Friendly Nature

In an era where environmental consciousness is paramount, tinplate lids shine as an eco-friendly packaging solution. They are recyclable, reducing the overall environmental impact and promoting a sustainable approach in packaging practices.

D. Versatility in Design and Size

Tube packaging with tinplate lids offers unparalleled versatility in terms of design and size. Manufacturers can create customized packaging solutions, catering to the specific requirements of different products. This flexibility allows for creative branding opportunities and unique packaging designs, enhancing the overall consumer experience.

V. Applications in Various Industries

A. Cosmetics and Personal Care Products

Cosmetic products often require premium packaging to reflect their quality. Tube packaging with tinplate lids not only offers an elegant and durable solution but also ensures that the sensitive formulations within remain intact and unaltered.

B. Pharmaceuticals and Medical Industry

In the pharmaceutical sector, maintaining the integrity of medicines and medical devices is paramount. Tinplate lids provide a reliable packaging solution, safeguarding pharmaceutical products from external contaminants and ensuring the safety of consumers.

C. Food and Beverage Sector

The food and beverage industry benefits immensely from tube packaging with tinplate lids. Whether it's sauces, spreads, or beverages, tinplate lids preserve the freshness and flavor of the products, ensuring that consumers enjoy a high-quality culinary experience.

D. Industrial and Automotive Products

Even in industrial and automotive sectors, where robust packaging is crucial to protect intricate parts and components, tinplate lids find their application. Their durability and resistance to harsh conditions make them an ideal choice for packaging in these industries.

VI. Innovations in Tube Packaging

A. Creative Designs and Branding

Tube packaging with tinplate lids opens avenues for creative designs and branding opportunities. Manufacturers can leverage advanced printing techniques to create visually appealing packaging, enhancing brand visibility and consumer engagement.

B. Smart Packaging Technologies

The integration of smart packaging technologies, such as RFID tags and QR codes, has transformed conventional packaging into interactive and informative mediums. Tinplate lids, with their smooth surface, facilitate the seamless integration of these technologies, providing consumers with valuable product-related information.

C. Sustainable Initiatives in Tube Packaging

The packaging industry is witnessing a shift towards sustainable practices. Tinplate lids, being highly recyclable, align with this eco-conscious trend. Manufacturers are increasingly adopting recycled tinplate, reducing the demand for new raw materials and contributing to the conservation of natural resources.

VII. Manufacturing Process of Tube Packaging with Tinplate Lids

A. Tube Production

The production of the cylindrical tubes involves precision engineering. Steel sheets are shaped into tubes using advanced machinery, ensuring consistency in size and shape. These tubes provide the structural framework for the packaging.

B. Lid Fabrication and Assembly

The tinplate lids undergo a meticulous fabrication process. The coated steel sheets are cut, stamped, and shaped to create perfectly fitting lids. These lids are then sealed onto the tubes using specialized techniques, ensuring a secure closure that prevents any leakage or tampering.

C. Quality Control Measures

Stringent quality control measures are implemented throughout the manufacturing process. Advanced technologies, such as automated inspection systems, are utilized to detect even minor defects. This attention to quality guarantees that the end products meet the highest standards of durability and safety.

VIII. Environmental Sustainability

A. Recyclability of Tinplate Lids

Tinplate lids are highly recyclable, making them an environmentally responsible choice. When recycled, tinplate can be repurposed into various products, reducing the need for raw materials and minimizing the overall environmental impact.

B. Reduced Carbon Footprint

The production of tinplate lids from recycled materials significantly reduces the carbon footprint associated with manufacturing. By promoting the use of recycled tinplate, industries contribute to the reduction of greenhouse gas emissions and energy consumption, supporting global efforts to combat climate change.

C. Eco-Friendly Disposal Methods

In addition to being recyclable, tinplate lids can be disposed of in an eco-friendly manner. Proper waste management systems ensure that these lids do not end up in landfills, further minimizing their environmental impact. Recycling facilities play a crucial role in ensuring the responsible disposal of tinplate lids, completing the sustainability loop.

IX. Challenges and Solutions

A. Cost Challenges in Manufacturing

While tinplate lids offer numerous advantages, the cost of manufacturing can be a challenge for some businesses. However, advancements in manufacturing technologies and increased demand for sustainable packaging solutions have led to economies of scale, making tinplate lids more cost-effective over time.

B. Addressing Environmental Concerns

The packaging industry faces growing concerns regarding environmental impact. To address these concerns, manufacturers are investing in research and development to create innovative, biodegradable materials. While tinplate lids are recyclable, ongoing efforts focus on developing eco-friendly alternatives that further reduce environmental impact.

C. Technological Advancements to Overcome Challenges

Technological advancements, such as automated production processes and precision engineering, have played a pivotal role in overcoming challenges associated with tinplate lid manufacturing. These advancements not only enhance efficiency but also contribute to cost reduction, making sustainable packaging solutions more accessible to businesses of all sizes.

X. Future Trends in Tube Packaging with Tinplate Lids

A. Integration of Smart Packaging Technologies

The integration of smart packaging technologies, including RFID and NFC tags, is expected to become more prevalent in tube packaging. These technologies provide consumers with real-time information about products, enhancing user experience and ensuring product authenticity.

B. Increased Focus on Biodegradable Materials

While tinplate lids are recyclable, the industry is witnessing a surge in research and development efforts focused on biodegradable materials. Manufacturers are exploring innovative solutions derived from natural sources, ensuring that packaging materials decompose naturally, further reducing environmental impact.

C. Customization and Personalization Trends

Customization and personalization are expected to be key trends in the future of tube packaging with tinplate lids. Businesses are likely to invest in unique packaging designs, tailored to specific products and target demographics. This trend not only enhances brand identity but also creates a memorable and engaging experience for consumers.

XI. Conclusion

A. Recap of Key Points

Tube packaging with tinplate lids represents a harmonious blend of durability, sustainability, and creativity in the packaging industry. Its ability to preserve product freshness, coupled with its eco-friendly nature, positions it as a frontrunner in modern packaging solutions.

B. Future Prospects of Tube Packaging with Tinplate Lids

As industries continue to prioritize sustainability and consumer engagement, tube packaging with tinplate lids is poised for significant growth. With ongoing advancements in manufacturing technologies and a focus on eco-friendly materials, the future holds promising prospects for this innovative packaging method.

C. Encouragement for Sustainable Choices in Packaging

In the pursuit of a greener and more sustainable future, businesses and consumers alike are encouraged to embrace packaging solutions like tube packaging with tinplate lids. By making conscious choices, we can collectively contribute to a healthier planet while enjoying the benefits of innovative and reliable packaging solutions.

関連商品