Shelf life, in this advanced food and beverage industry, is of much necessity for packaged items to have a long and safe life when consumed by humans. Justifying the importance of the shelf life and ensuring zero contaminations that tend to arise during storage and in transit guarantees consumer satisfaction. The best practice to achieve this is using tinplate lids. This paper discusses the effect of the use of tinplate lids in improving the shelf life of packaged items based on very stringent and realistic data.

Understanding Tinplate Lids

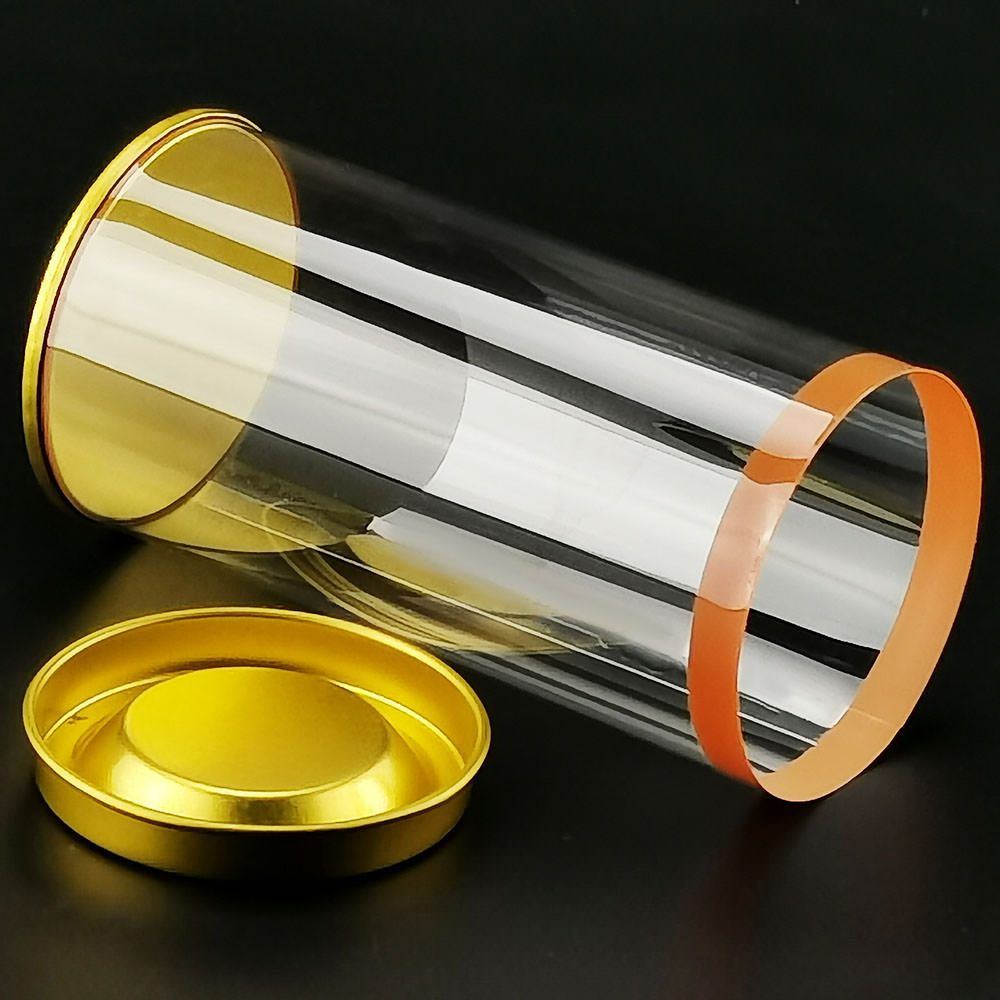

Tinplate is a thin steel sheet coated with tin. This product is well known for its amazing resistance to corrosion, strength, and formability, and, thus, it is fit for use in packaging applications. Tinplate lids have found use in the food and beverage industry majorly for the quality of sealing that they offer: that a tinplate lid gives a hermetic seal, ensuring the quality and safety of contents.

Composition and Manufacturing Process

Tinplate is a kind of further plating with tin over rolled steel by means of electroplating. Such a coating bears plenty of protective functions and shows the positive outcome for the steel, as it will be more rust- and corrosion-resistant. On each side, the thickness of the tin coating is approximately 2.8 microns, though this may vary. It is just this extremely thin but effective coating that makes tinplate unique in its features.

Benefits of Tinplate

Airtight Sealing

One of the major merits of tinplate lids is that they are airtight. For instance, it provides an effective barrier to reduce oxygen and moisture ingress, which are strong sources of contamination if they reach the product and affect it. There have been many studies that showed oxygen and moisture as the two most main conditions responsible for the spoilage of food products. An effective barrier for the factors can be well provided by the tinplate lids, thus protecting the product against any failure of freshness and safety in its content.

Corrosion Resistance

The other area that tinplate is said to be successful in giving a package content a longer shelf life is through corrosion resistance; the tin coat provides protection against oxidation and rust of the steel underneath. More so, this is important for a food content that can be sold with acids or alkaline substances, known to turn some metals, thereby causing corrosion. This implies, therefore, that corrosion resistance with tin plate guarantees that packaging remains unbroken and contents are not contaminated by rust or metal ions.

Strength and Durability

Tinplate lids are also strong and durable. They can withstand intensive mechanical stress under handling, transportation, and storage without any deformation or broken parts. In so doing, its contents are given the much-needed tamper resistance and spoilage protection, hence extending the shelf life of products. Besides, tinplates are formable in designs, therefore making it flexible in the formation of the lid shapes for different packaging solutions.

장벽 속성

Tinplate lids offer excellent gas, light, and moisture barrier capabilities. Light, in particular the ultra-violet component of light, can become a degrading agent for some food products and calls for chemical changes. The opacity in the tinplate creates an immense barrier to light, thus affecting the contents with their quality and nutrients. Equally, it is said that tinplate is impermeable to gases and moisture, which hence hinders spoilage and prolongs the product shelf life.

Realistic Data Supporting the Benefits of Tinplate Lids

Thus, some critical empirical evidence of the same from scientific research and industry reports is essential for support and validation to the merits of tinplate lids. Some critical findings that show how useful the tinplate lids are to improve the shelf life of packaged products are as below:

Study of Oxygen Transmission Rate (OTR)

An investigation that was done by the Institute of Food Technologists (IFT) on the various packaging materials inclusive of tinplate showed that; it was less than 0.1, cc/m²/day. On the contrary, the same is very low compared to plastic and paper-based materials. This must therefore mean that it has advanced barriers that do not allow oxygen entry into the package and cause food spoiling.

Corrosion Resistance Evaluation

This was supported by research in the Journal of Packaging Technology and Science, which confirmed the corrosion resistance ability of tinplate in the various environmental conditions. The tinplate showed very high levels of resistance to corrosion with no crucial destruction observed, even in lengthy exposure to humid and acidic environments. That ensured the tinplate lids were firm enough to keep the packs watertight.

Shelf Life Extension

An industry report of the Can Manufacturers Institute (CMI) revealed comparisons of shelf life of canned foods sealed with tinplate lids with those using alternative materials. Based on the findings, products sealed with tinplate lids extended their shelf life by as much as 30% over those that had plastic or aluminum lids. Such data is indicative of the effectiveness of tinplate in holding the capability to keep food products preserved over the long term period.

Mechanical Strength Analysis

An assessment of the mechanical strength of the tinplate lids was made under variations of stress conditions by the FPRA. According to the results, the tinplate lids can resist a pressure of up to 250 kPa and keep their form without breaking; very resistant and able to guarantee their contents that are being transported or stored in them.

Applications of Tinplate Lids in the Food and Beverage Industry

There are a number of applications that tinplate lids find both in food and drink markets. Just to mention a few such applications are:

Canned Foods

The number-one food value items, like vegetables, fruits, soups, meats, derive great advantages from the use of tinplate lids. The tinplate is airtight and corrosion-resistant, thus containing foods safely and nutritiously for a long duration.

Beverages

The application of tinplate lids in beverage packaging is one other common application, particularly for soft drinks, juices, and alcoholic drinks. The barrier properties of tinplate prevent carbonation loss in fizzy drinks and protect the flavor and quality of the beverages.

Baby Food

Safety and quality are important in baby food. Tinplate lids protect against contamination and spoilage to give surety to the food.

Ready-to-Eat Meals

The tinplate lids will provide the ready-to-eat meal packages with an extended shelf life. Linked to this, such forms of lids will make the products convenient and safe for the consumers due to tolerance of environmental factors and also the convenience of long-term storage.

Environmental Considerations

Although the tinplate lids contribute to extending the shelf-life and assuring safety of the product, its impact on the environment has to be given due consideration. Tinplate is a material that can be recycled. The steel and the tin part of it can be retrieved and reused. The recycling of tinplate combines the conservation of raw materials and energy resources; it preserves the environment when compared to nonrecyclable packaging materials.

Recycling Rates

According to the Steel Recycling Institute, the recycling rate of tinplate packaging material in the USA is close to 70%. The same is observed with a higher rate in Europe and some other regions. Such a high level of recycling, in a way, reveals environmental benefits accrued in tinplate usage for packaging.

결론

The paramount importance of tinplate lids is their contribution to improved shelf life for contained products. The application of tinplate lids in the food and drink industry for a variety of products ensues from their impermeability, resistance to corrosion, mechanical strength, and barrier properties. Warner reasons that it is owing to these attributes that empirical data and industry reports show tinplate lids for their proven effectiveness in the preservation of quality and safety of packaged products, thus justifying them as a reliable and sustainable option for manufacturers.

The existence lies in effective packaging solutions with rising consumer demand for safe, long-lasting packaged products, as in the case of tinplate lids. Manufacturers can opt to use tinplates to keep their products fresh, safe, and palatable to the consumer, which is in line with sustainability toward the environment by recycling.

관련 제품