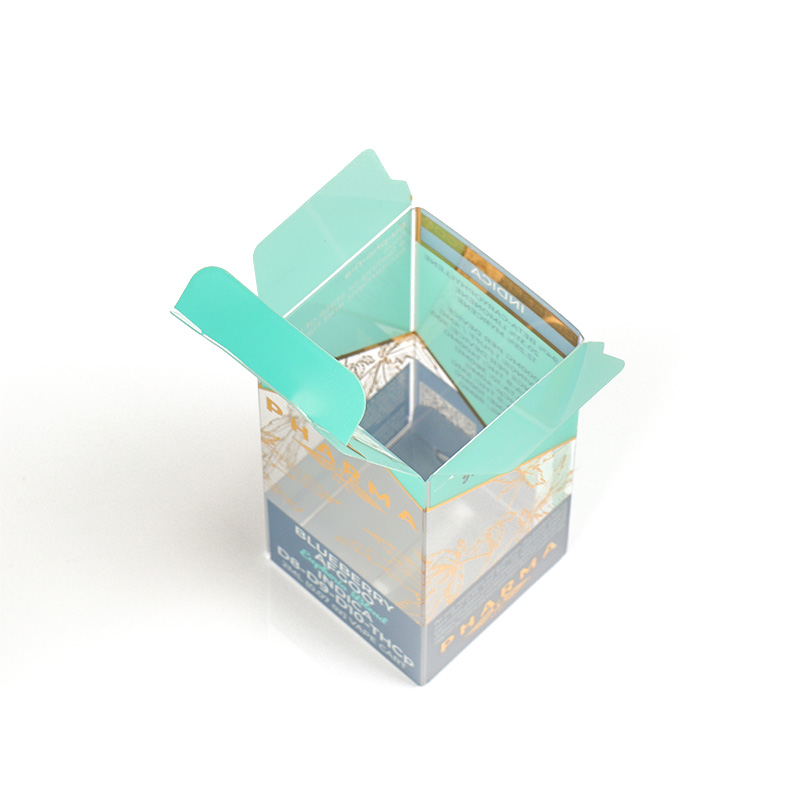

Custom plastic box packaging is a type of packaging box designed to meet individual needs. It is made of premium plastic, is precisely machined, and has outstanding waterproof and durability qualities. Your specific demands for product packaging may be met by customising this kind of packing box in terms of size, colour, style, and printed content.

Features

- Premium plastic materials: To guarantee product safety, non-toxic and environmentally friendly plastic materials are employed. Transparency that is crystal clear highlights your merchandise.

- Customised size: We can make packing boxes in a range of sizes to suit your demands for both protection and display of varied sized and tiny items.

- Colour and style: To improve the perception of your brand, a range of colour choices are available. Moreover, distinctive styles may be tailored to your event's topic or brand.

- Printing and personalisation: Prints your logo, tagline, and other information on the packing box. Supports a number of printing techniques, including screen printing, heat transfer printing, etc.

- Sturdy and Waterproof: The robust construction keeps your items safe from harm thanks to its excellent durability and waterproof capabilities.

- Sustainable and environmentally friendly practices include encouraging sustainable development, adhering to environmental regulations, and utilising recyclable materials.

- Economical solution: affordable pricing without sacrificing quality. For even more cost reductions, bulk purchases are eligible for discounts.

- Simple to use: Product insertion and assembly are made easier by the user-friendly design. firmly closed to avoid accidental opening while being transported.

Customization process

- Give specifications: You give detailed instructions for the packing boxes, such as dimensions, colour, design, and kind of printing.

- Design and proofing: Create designs that meet your requirements and provide proofs for your approval.

- Verify production: We'll begin batch production as soon as you provide your approval for the proofreading.

- Check the completed packing boxes for quality to make sure they fulfil your specifications.

- Delivery & shipping: Send the package to the address you choose.

- After-sales support: Offer thorough post-purchase assistance to address any issues you may run across while using the product.

plastic box material

It's best to carefully evaluate a variety of elements when choosing materials for custom plastic box packing, including the product's nature, the usage environment, the requirement for protection, and the budget. In order to lessen adverse effects on the environment, materials that adhere to environmental protection regulations should be used.

- Polyethylene (PE): Polyethylene is a typical plastic substance that has outstanding resistance to heat, cold, and moisture. It is often used in the packaging of common goods as well as food. Low density polyethylene, high density polyethylene, and linear low density polyethylene may all be classified based on density.

- Polypropylene (PP) is a transparent plastic substance that has a high mechanical strength and resistance to heat. It is often used to create food packaging and microwaveable dinnerware that can tolerate greater temperatures.

- Polyvinyl chloride, sometimes known as PVC, is a robust and durable material that is frequently used to manufacture packing boxes that must endure high pressure and friction. Nonetheless, PVC manufacture might result in the release of hazardous materials, thus selection must be done carefully.

- Polyethylene terephthalate, or PET, is a transparent plastic that is very resilient to heat. Food packaging and beverage bottles are often made using it. PET complies with environmental protection regulations and is recyclable and reusable.

Applicable industries and scenarios

- Electronic products: Tablets, digital cameras, cell phones, and other items may be shown and protected with custom plastic box packing. The plastic box may significantly lessen product damage during transit since it includes certain shock- and scratch-proof features. In order to improve the appearance of the goods, personalised plastic boxes may also be printed with company logos, product details, etc.

- Presents: Personalised plastic box packaging may be utilised to accentuate the texture and elegance of the present. The present may be made more unique and unforgettable by adding personalised aspects, such as printing blessings, designs, etc., on the plastic box.

- Food: The food business uses customised plastic box packaging for a variety of products, including chocolate, candies, cookies, and more. Food shelf life and flavour are ensured by plastic packaging' excellent sealing capabilities. Additionally, branded plastic boxes may improve food's market competitiveness and brand image.

- Cosmetics: Lipstick, eye shadow, foundation, and other cosmetics may be packaged in personalised plastic box packaging. Plastic packaging may guarantee the longevity and quality of cosmetics due to their unique light-shielding characteristics. Additionally, personalised plastic boxes may improve the product's appearance and brand perception.

- Daily requirements: such as infants, clothing for the day, and other essentials.